Weight Optimization

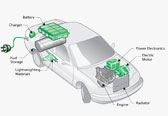

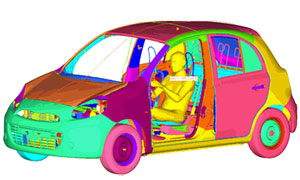

Weight optimization is a technique used mostly in the automobile industry to get the optimum weight or less weight of the desired part or product. Here parametric optimization also comes in handy to get the right design parameters to build the final product that is the concept design. The main objective of weight optimization is to build a concept design with less weight as compared to other designs.

DEP (Detroit Engineered Products) has been one of the prevailing companies to give desired results to the customers in India and USA. Both countries have good amount of reputed automobile industries, hence weight optimization becomes an important practice to get designs which have less weight, use less material for manufacturing and ultimately reduction in cost of the design. Weight optimization is mainly linked to get the right material i.e. metals, which have superior qualities compared to other metals. The weight optimization method includes four stages, reference model then simplifying the reference model. Third stage is to understand the areas of optimization on the volume of the structure and the last is to get the required concept design which is a solution to the problem and subsequently getting a design for manufacturability. Nowadays, the automotive industry has many variable constraints. Fuel consumption being the biggest constraint which is a widely researched topic, weight optimization or reduction plays a very important role in reducing the fuel consumption as reduced weight is directly linked to reduced energy consumption.DEP (Detroit Engineered Products) has a well-versed team in this field and have services in India and USA, the skilled team of the company will help you get the optimum concept design to your product or part.

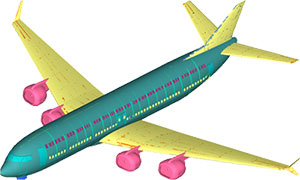

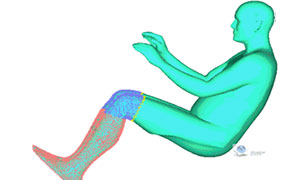

DEP (Detroit Engineered Products) has a deep background in engineering solutions and product development field, the industries in which it provides services is Aerospace and Defence, Automotive, Medical Devices and Construction equipment. DEP (Detroit Engineered Products) has helped many organizations and business to grow and earn profits, as weight optimization will give you designs which are require less material and ultimately less cost to manufacture.