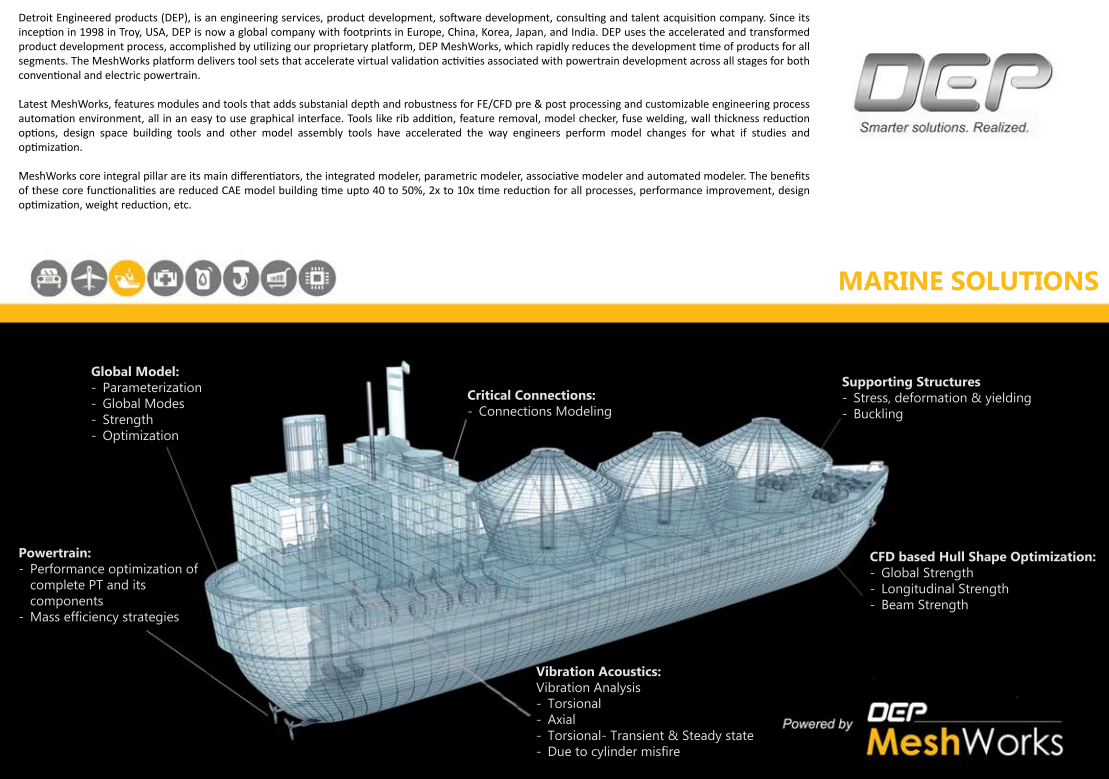

Recent advances in the maritime industry have led to the emergence of new designs with improved seakeeping qualities and significantly increased velocity. Existing ship types, such as bulk carriers, general cargo carriers, tankers, gas carriers, and container ships, have also been modified. While frigate designs have significantly changed, the propulsion systems that are now in use have also changed dramatically. The design and development process must be cost-effective, require minimal manpower, be available when needed, and be not overly vulnerable. The safety of the ship, its crew, and the environment in which it sails are all critical. With more than 2 decades of experience from completing many projects and programmes, DEP team can assist in marine product development from the concept and production at a faster pace. Our experts team can help from design phase of development to engineering support and plan review, as well as technical services, and deliver quality results for manufacturers in newbuild projects.

- Parameterization using DEP’s standard process:

- Shape

- Structural

- Topology

- Welds

- Adhesives

- Composites

- Bulkheads

- Doublers

- Engineering:

- Offshore marine engineering

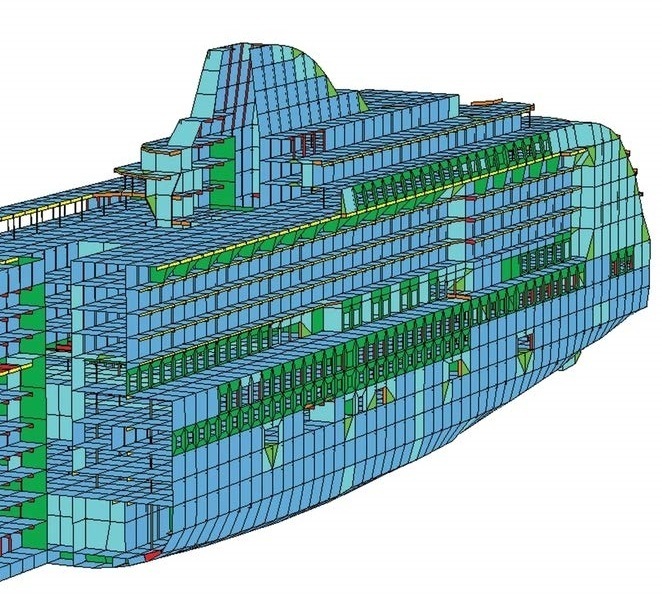

- Ship structural design & analysis

- Vibro acoustic analysis

- Metal to composites engineering

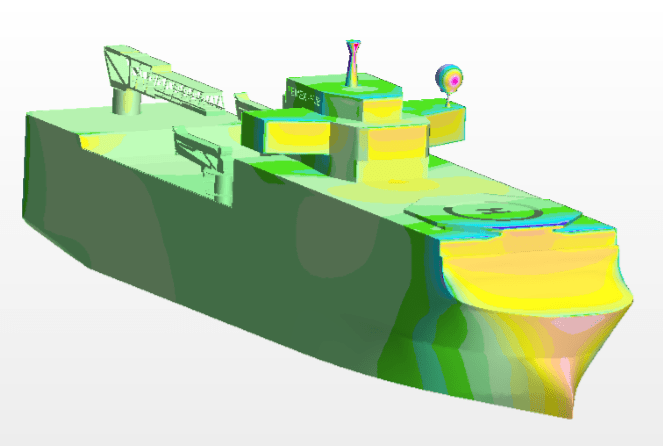

- Computational fluid dynamics

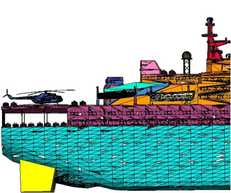

- Ship configurations:

- Tankers

- Bulk Carriers

- Container Ships

- Ocean Liners

- Modeling of Critical Areas :

- Connections

- Openings

- Bracket Toes

- Structural Knuckle Points

- Primary, Secondary and Tertiary bending on Global FE model

- Stress and Deformation of main supporting members for Yielding and Buckling

- Vibroacoustic Analysis

- Global Bending Modes

- Torsional Modes

- Bulkhead Stress Analysis

- Deformation and Buckling

- Composite Ply Optimization

- Acoustic Cavity Model Building

- Structure-Acoustic Coupling

- Forced Frequency Response

- Acoustic Response

- Weight Optimization:

- Alternate Configurations

- Alternate Materials – Composite

| Body & Exteriors | Interiors | Engine System |

| Hull | Forecastle | Bedplate |

| Keel | Fore mast | Crankshaft |

| Bow thrusters | Bridge | Camshaft |

| Bow | Afterdeck | Frame Box |

| Propeller | Foredeck | Piston |

| Rudder | Piston Rings | |

| FreeBoard | Connecting Rod | |

| Stern | Cylinder Head | |

| Inlet and Exhaust Valves | ||

| Turbocharger |