Generating a high-quality mesh is a critical task for CAE users. It allows for a detailed view of the design and provides important insights. To achieve a good mesh, the underlying geometry must be analyzed, and the best quality mesh should be applied. A mesh that meets the objective is the right choice for the given scenario. It’s important to use a mesh that is of reasonable quality and tailored to the specific problem to ensure the solver produces accurate results.

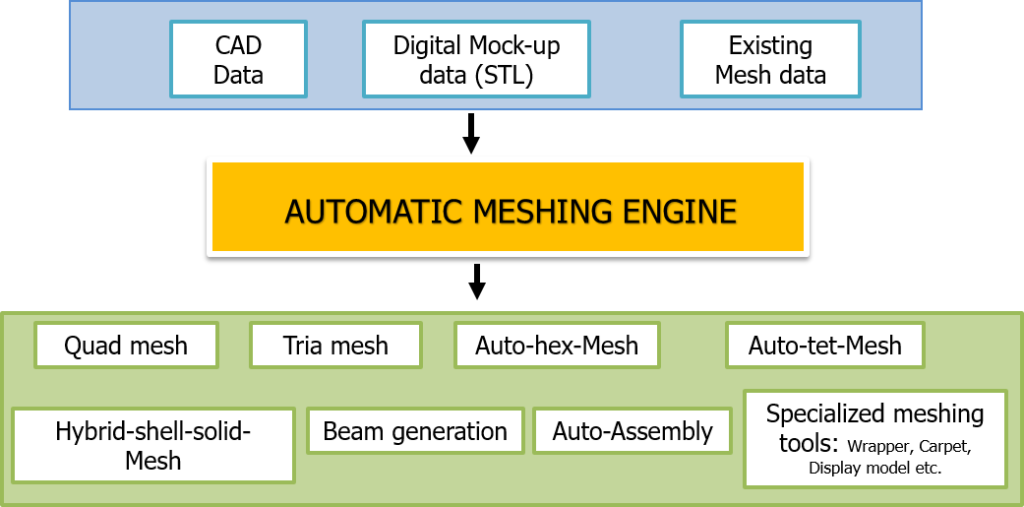

MeshWorks features a powerful CAE meshing engine that enables users to rapidly generate 2D and 3D meshes from intricate CAD data, including Tetra, Sheet Metal, Mid-plane, and Hexa. With highly automated meshing functions, users can produce high-quality meshes with minimal intervention and in the shortest possible time, without the need for extensive CAD clean-up. The system also offers template-based meshing, allowing users to set up templates for feature recognition, mesh size requirements, and quality criteria. Additionally, MeshWorks provides automated mesh quality improvement functions, ensuring meshes meet user-specified quality templates and constraint criteria.

MeshWorks supports a wide range of CAD interfaces, enabling users to import geometries from popular CAD packages and generic formats like STEP and Para solid. MeshWorks also includes a comprehensive set of CAD functions for curve, surface, and solid editing and manipulation. Additionally, the system provides batch meshing capability, allowing users to assign meshing templates to entire model assemblies and mesh them in a batch mode across multiple processors – on workstations or in the HPC environment.

The AI/ML based feature recognition engine in MeshWorks produces higher geometric accuracy. The system also offers template-driven meshing, enabling enormous mesh control for features such as fillets, tubes, chamfers, and machined faces. Additionally, MeshWorks includes powerful feature removal and suppression tools, which allow users to create simplified meshes for specific CAE workflows by removing features like fillets, ribs, and bosses. Furthermore, MeshWorks boasts the widest range of hex meshing functions, including auto-cartesian-hex mesher and parametric extrusion hex mesher.

With a recent update, MeshWorks continues to set new standards, enhancing its Meshing module to deliver even more precision, efficiency, and versatility in mesh generation. This innovative upgrade promises to revolutionize the way engineers approach complex geometries, enabling seamless integration with various simulation tools and accelerating the product development lifecycle. Join us as we delve into the advancements of MeshWorks’ Meshing module, where precision meets performance to redefine engineering excellence.

Key Meshing Features:

Hexa Meshing:

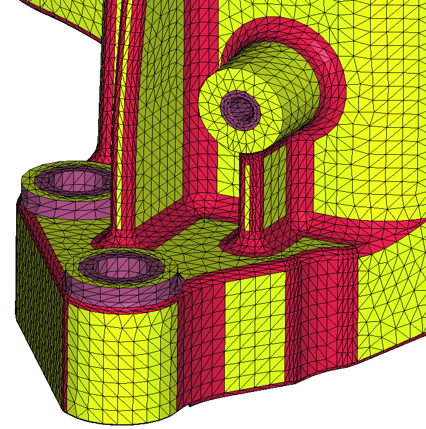

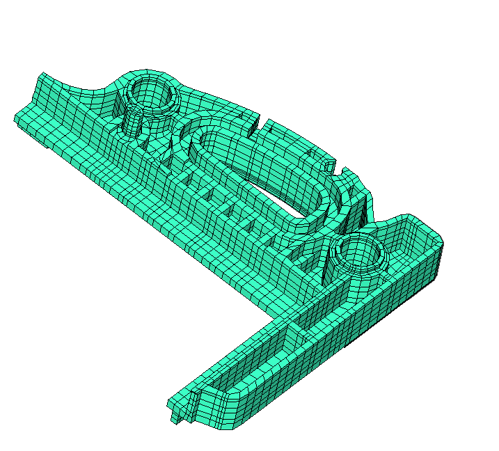

- Auto HexMesh: MeshWorks introduces an entirely automated tool for generating high-quality HexMesh, revolutionizing complex geometry meshing with a single click. Ideal for intricate models like Seat Foam, Bumper Foam, and Calipers, it streamlines the meshing process.

- Extruded HexMesh: Experience precision and flexibility with MeshWorks’ highly automated, process-driven Extruded HexMesh tool. Perfect for capturing intricate features like Rib Draft angles, it ensures accuracy in models such as Mounts, Rotors, and Housings.

- Hexa from MidShell:MeshWorks offers an automated solution for generating Hex Mesh from MidShells, tailored for thin-walled structures, enhancing efficiency in mesh creation.

- Hex Cutter: Enhance productivity with MeshWorks’ fully automated Hex Cutter tool, enabling quick removal of elements in specific regions while maintaining high element quality. Ideal for creating Holes, Slots, and Arbitrary Re-Entrant profiles with precision.

- Solid Fuse Seamlessly fuse complex interaction regions of different Hexa geometries with MeshWorks’ Solid Fuse tool, ensuring node-to-node connectivity and enhancing workflow efficiency.

Tetra Meshing:

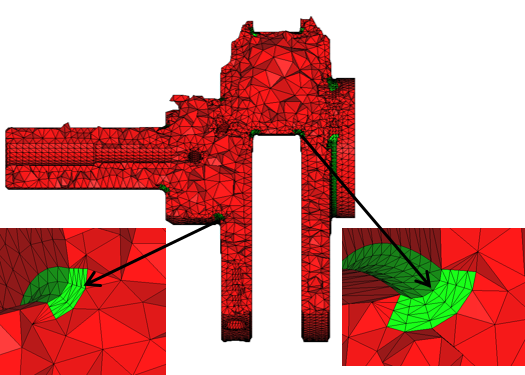

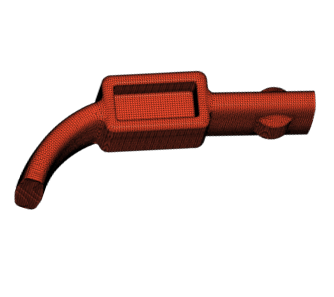

- Auto Tetra Meshing: MeshWorks presents a completely automated template-based solution for high-quality Tetramesh generation from CAD parts. Recognizing features like Fillets, Tubes, and Chamfers, it offers various meshing algorithms catering to diverse needs.

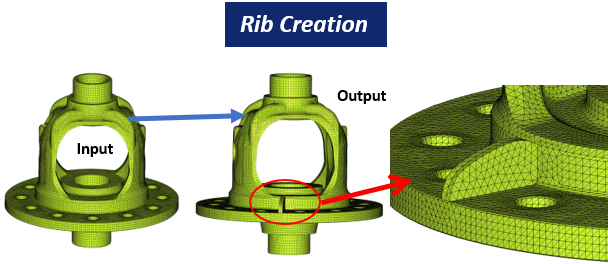

- Tetra Feature Creation/Modification Tools: Experience enhanced flexibility with MeshWorks’ Solid Boolean tools, facilitating Union of Tetra meshes, creation of Tetra Ribs, and automatic Feature Removal, optimizing mesh quality and efficiency.

- Tetra Meshing Enhancement:Enjoy optimized tetra mesh gradation control in MeshWorks, reducing tetra count for efficient model production without compromising feature capture and quality requirements.

Plastic Meshing:

- Auto Mid Plane Meshing: MeshWorks introduces a completely automated solution for extracting high-quality Midmesh from 3D CAD parts, offering hierarchical relationship for effortless modifications.

- Automated Thickness Assignment: Simplify thickness assignment with MeshWorks’ automated tools, including Layered Thickness assignment for Ribs with Drafts, streamlining the meshing process.

- Cross Rib / Pattern Rib Creation:MeshWorks offers automated tools for creating Ribs on complicated base meshes, with the capability to generate Pattern Ribs with absolute Node to Node connectivity, enhancing mesh quality.

- Mid Mesh Validation:Validate mid mesh for node issues both inside and outside geometry with MeshWorks’ tools, accurately identifying and resolving model’s free edges.

- Thickness Assignment:MeshWorks provides advanced thickness assignment tools, allowing precise customization of variable thickness to meet specific requirements.

- CAD Mesh Compare:Identify and reuse Finite Elements from previous design iterations with MeshWorks’ CAD Mesh Compare tool, optimizing workflow efficiency.

- Feature Replicate:Replicate features across model inputs at the FE level with MeshWorks, ensuring consistency and accuracy in element replication.

Sheet Metal Meshing:

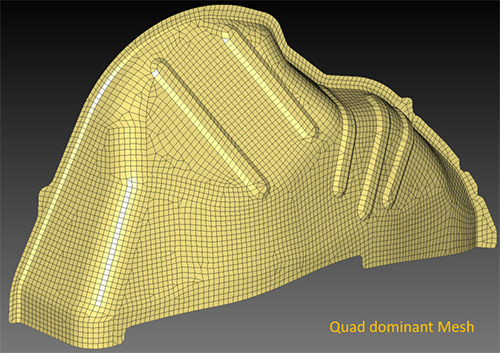

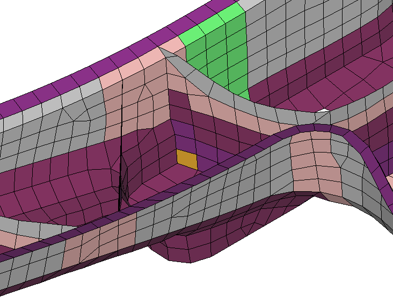

- Mesh Parameters: MeshWorks offers a completely automated mesh creation function, empowering users to create high-quality meshes with user-defined inputs, ensuring smooth mesh flow.

- Interactive Batch Mesher: Create structured and quality mesh based on various input parameters with MeshWorks’ Interactive Batch Mesher, featuring feature removal and suppression tools for optimal mesh flow.

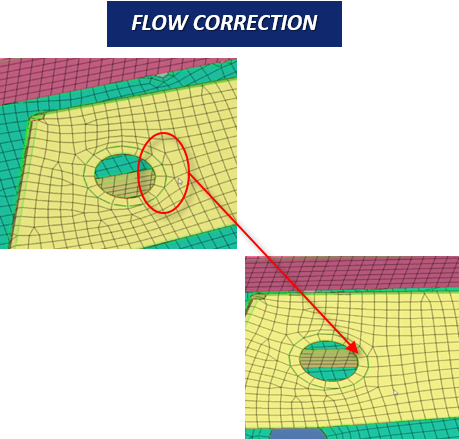

- Flow Correction & Feature Capturing:Access a wide variety of correction features under MeshWorks’ mesh editing tools, enhancing mesh quality with both manual and auto correction methods, supported by automated thickness assignment and feature capturing.

Template Based Meshing:

- MeshWorks introduces template-based meshing, offering users enhanced customization possibilities and control over mesh creation, from mesh parameters to model treatment and fillet selections, ensuring maximum feature capturing and quality reseeding.

Benefits:

- MeshWorks offers a significant improvement in CAD clean-up, resulting in a drastic reduction in post-mesh correction time.

- It also delivers significantly higher element quality compared to other market tools, further reducing meshing turn-around-time (TAT).

- With MeshWorks, users have access to all types of superior meshing options, including tetra, hexa, plastics, sheet metal, and more, all in one software.

- This eliminates the need for multiple meshing software and results in significant cost and time savings.

- MeshWorks reduces total meshing time by 30% to 50% across various model types while maintaining high mesh quality. Additionally, when using the same meshing and quality templates, MeshWorks produces a lower tetra count compared to competitors, ultimately reducing analysis run-time.

How does MeshWorks compare to other similar software?

| Features | MeshWorks – Meshing | Similar softwares |

| Automated Mesh Editing Tools | ✔️ | ❌ |

| Unique Hex Meshing Functions | ✔️ | ❌ |

| Faster Meshing Turn- Around-Time | ✔️ | ❌ |

| Customized Automated | ✔️ | ❌ |

| Meshing Tools | ✔️ | ❌ |

| Industry-Leading Meshing Engine | ✔️ | ❌ |

| Feature Capture with Quality Requirements | ✔️ | ✔️ |