Due to technological advancements, today’s competitive market is dominated by innovation and its rapid implementation. As an engineering technology firm, DEP provides reverse engineering services for any product or equipment, allowing you to improve design while monitoring manufacturability and the development process. Our qualified engineering team has gained extensive experience in reverse engineering projects over the last few years. Furthermore, our cutting-edge software tools ensure that the physical object models are ready for analysis, design optimization, or manufacturing. Many organizations choose us as a partner because of our expertise in various disciplines such as design validation and optimization, finite element analysis, and product engineering. We provide reverse engineering support to customers at all stages of product development to determine the original design intent, modernize manufacturing processes, or design a new part to fit a legacy part, among other things.

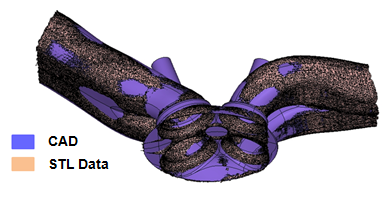

Understanding the purpose of the component or assembly is critical to every reverse engineering technique. DEP’s qualified engineers employ numerous geometric and tolerance methodologies to stack tolerances and have experience based on actual design work to illustrate the efficacy of the process. All these processes are based on the understanding of how the part/assembly interacts with other components in the system. DEP provides reverse engineering service to customers at various stages of product development to establish the original design intent, modernize manufacturing processes, or create a new part to fit a legacy part, etc. Using the most up-to-date abilities and technologies, our experts can deliver ideal solution tailored to each client’s specific needs.

DEP Value Addition:

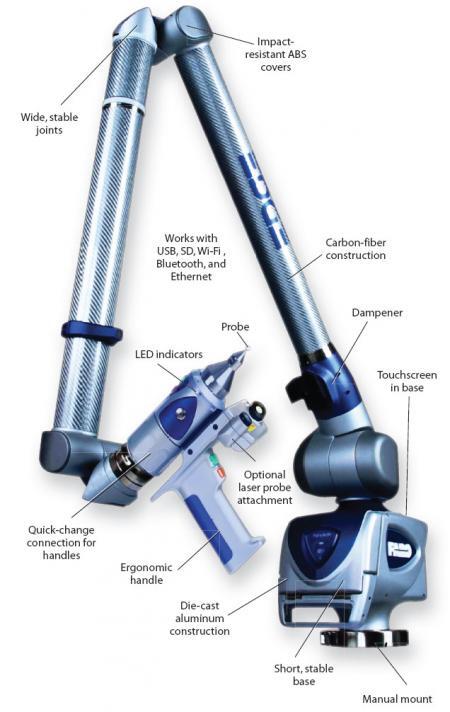

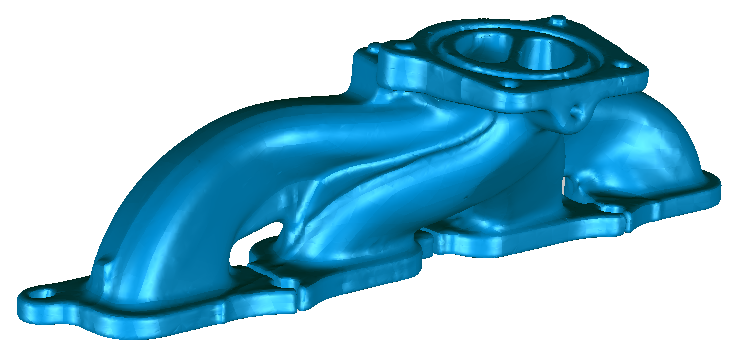

- 3D Laser scanning technology to capture physical parts accurately

- Scalable services to ramp up engineering requirements

- Comprehensive reports and insights about the product feature

- Decades of experience in actual design work to verify the efficacy of the process

- Manufacturing support through prototyping and other modernization activities

DEP Reverse Engineering services:

- Part Scanning Services

- Computer- Aided Verification (CAV)

- Benchmarking Services

- Detailed Part Specifications Services

- Other analysis supports – Manufacturability, Design for Manufacturing and Assembly, Material analysis, etc.

- Modeling support

Customer Benefits:

Our savvy professionals can deliver high quality services that are customized according to the need of the customers at an unmatched pace. The design team at DEP can add value by identifying areas for improvement and rectify them as part of the RE task. Our consultative and problem solving approach provides:

- Data for different types of simulation processes

- Time and cost-effective Product Development Methodology

- Optimized quality and process plan

- Enhance agility for the product towards market drifting direction

- Focus on product enhancements