Every system or a product must meet certain safety and high performance requirements. These complex systems are built by mechanical, electrical, pneumatic and hydraulic components in addition to sensors and microprocessors with varying degrees of interactions. The physical properties of all interconnected components and sub-systems exert influence on one another during every operating situation. It must be described precisely in mathematical ways and their behavior is thoroughly evaluated using the simulation. 1D simulation is used to simulate systems, allowing engineers to better understand how the various components within the system interact. To define one-dimensional objects, we can work with fewer parameters, which requires fewer equations to be included in the simulation. Thus, saving time during the modeling and simulation process.

Domain Expertise

DEP offers global strategic engineering and environmental consultancy that specializes in performing 1D-CFD simulations.

Detroit Engineered Products (DEP) is capable in offering high level 1D system modeling that includes:

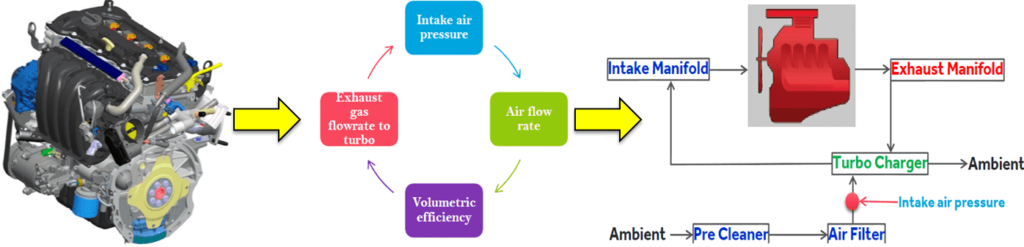

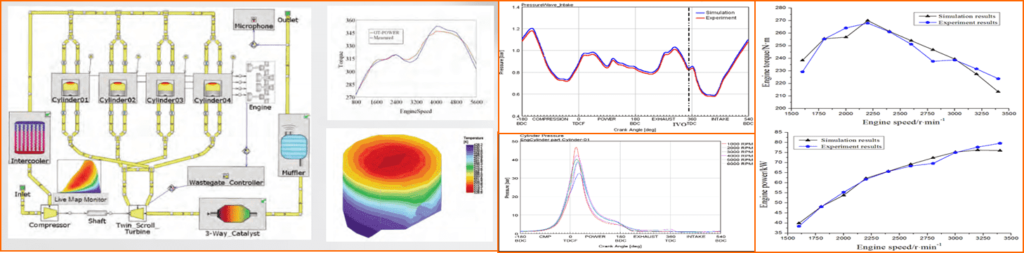

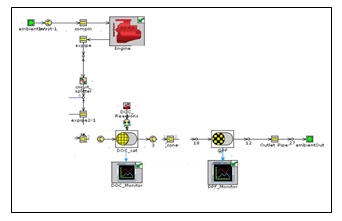

1. Engine Performance simulation

To improve the efficiency of overhaul powertrain and engine sub-system performance, detailed knowledge of the internal interactions in the engine is essential. This is where the analyzing of engine performance comes in to play. DEP has extended its frontier towards the technology development that includes operating strategies, combustion, fuel injection, boosting performance & engine down sizing

We carry 1d simulation for the prediction of performance parameters like Power, Torque , Airflow , Volumetric efficiency, Fuel consumption , Turbocharger performance with matching & pumping losses

- The simulations also aim to analyze for the following parameters

- Combustion analysis

- Pressure drop across air filter assembly

- Throttle performance and control

- Intake pressure wave dynamics

- Valve timing and control

- Cylinder pressure prediction

- Knock prediction

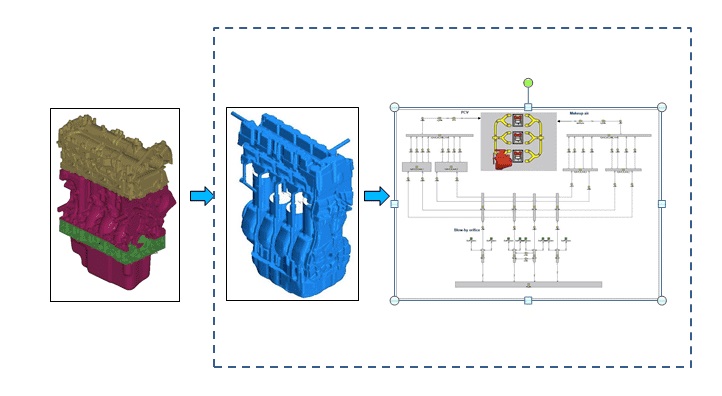

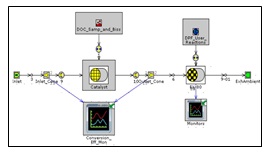

2. Positive Crankcase Ventilation – 1D Blow-by-simulation

The key objective of this technique is to vent out the Blow by gases ( constituting unburnt gas and oil vapors ) so as to not compromise on the adverse effect of pumping losses over the engine efficiency

DEP ensures broad application of 3D – 1D integrated modelling & simulation to analyze the Crankcase pressure inside the engine & the blow by production as a function of speed & load via PCV valve

The simulation focusses on performance optimization of PCV system by accurately matching the ventilation flow with blow by production characteristics while engine performance and drivability remain unaffected.

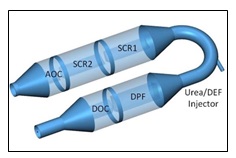

3. Exhaust After-treatment

Meeting the vehicle mission regulations has now become an unavoidable challenge. This in turn persuades to have a detailed understanding over the vehicle’s exhaust system & it’s after-treatment

The objective of this simulation is to analyze the multidimensional behavior of the after treatment components

With the extending capability in sub-system modeling ,DEP has stepped forth in carrying out the after-treatment simulations to analyze the chemical kinetics inside the system

The simulation mainly focusses on calibration the engine and after-treatment system for optimum fuel economy, performance and emissions.

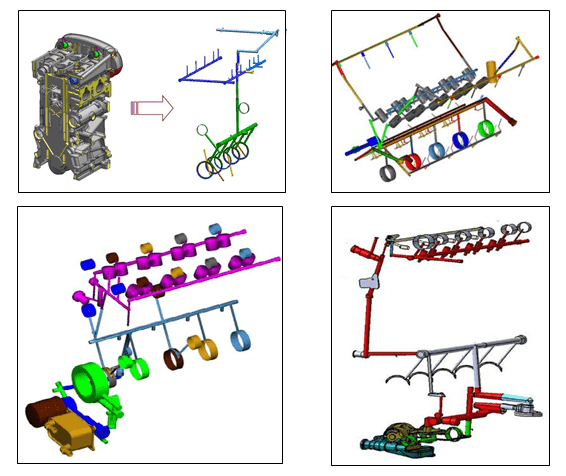

4. Lubrication simulation

DEP offers continuous support in providing the value added solutions in the field of tribology as well.

We have developed a detailed Lubrication model of crank train system for analyzing & optimizing the performance of lubrication systems

Steady state model development with subassembly model integration (Crank train & valve train) is developed by our team to actually predict the bearing loads.

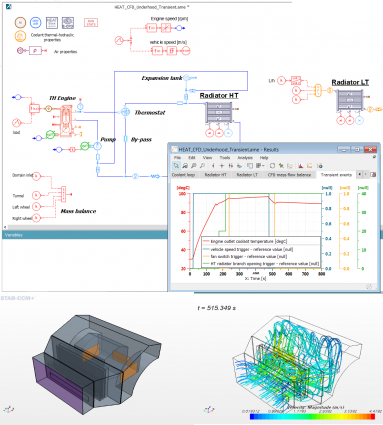

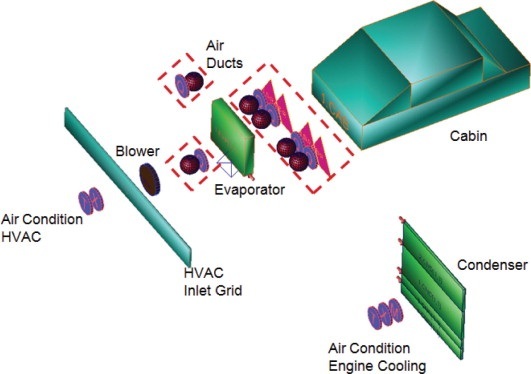

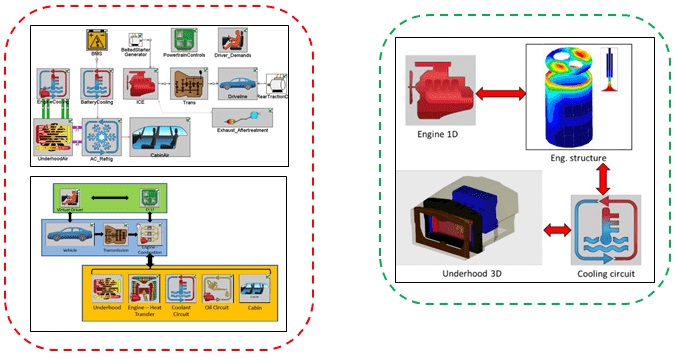

5. Vehicle Thermal management

With the flexibility over model based system simulation, DEP is consistent with the goal to provide the valuable solution for all the aspects of engine & vehicle systems.

Detailed modeling & building the vehicle thermal management system with the integration of built-in Finite Element cylinder structure has been carried out by our team for the actual prediction of heat flow and heat loss throughout the system.

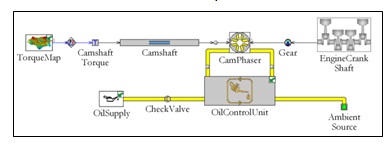

6. Variable valve actuation–1d Cam phaser simulation

Variable valve actuation–cam phaser Test setup & calibration DEP has carried out an extensive test bench setup for performing static and dynamic tests over variable valve actuation. The test includes

- Solenoid Force measurements

- Static Camphaser leak and operating tests

- Dynamic Camphaser leak and operating tests

The variable valve actuation becomes a key aspect of any modern engines to improve the engine’s efficiency

In addition to the physical tests, our team also carried out simulation of cam phaser assembly for validation with the experiments mainly to analyze the performance and sensitivity of the cam phaser with respect to solenoid actuation

The simulation aims on metering of flow rate, rate of phasing and leakages inside the cam phaser assembly.

We provide exceptional CAE Services and our commitment to provide industry leading System Simulation (1D-CFD) to the global clientele has continued to strengthen our reputation making us the chosen partner for engineering service in the market. We promise you the advantage of: