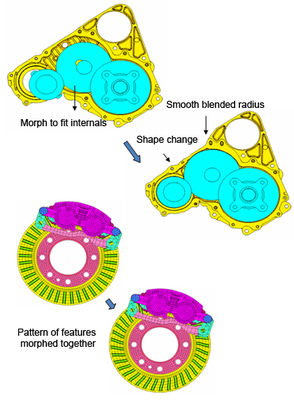

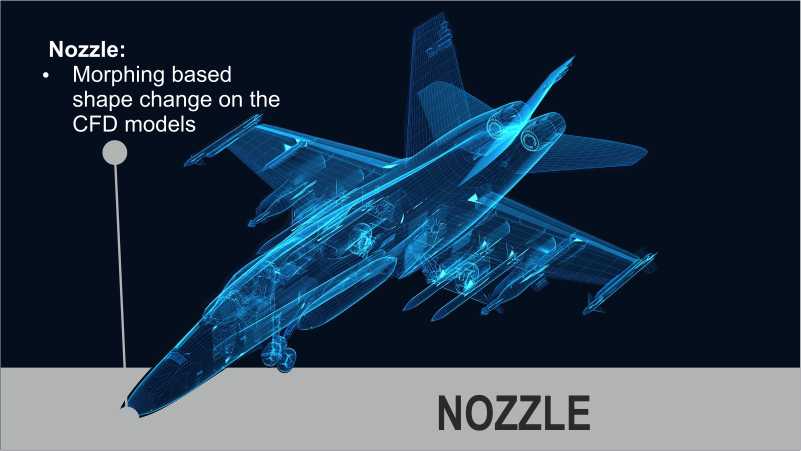

OEMs are looking for ways to eradicate non-value-added activities to increase their competitive-edge in the automotive industry. This will in turn increase the need for product development time reduction. As theme and packaging changes occur, CAD models will change according to rules that are considered as industry best practices. A variety of morphing techniques which are available in DEPMeshWorks tool can help meet various application requirements. This includes control block (lower and higher order), direct parabolic, spherical, polycube, and field based morphing. DEP MeshWorks is a feature-based morphing tool that can quickly change the geometry and proportions of existing FE and CFD models.

One of the most important features of parametric modelling is that interlinked attributes automatically change their features. Parametric modelling allows the designer to specify entire classes of forms rather than individual instances. DEP employs MeshWorks, a comprehensive CAE model parameterization engine that can be used at any stage of product development and supports a wide range of parameter categories. A large number of runnable CAE models can be generated automatically by exercising parametric CAE models.

Domain Expertise

Member repositioning:

- Shape parameter

- Structural (gauge / material) parameter

- Feature parameter

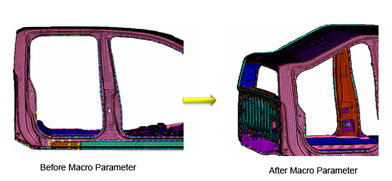

- Macro parameter

- Topology parameter

- General text parameter

- Connectors

- Stamped Features

- Loads & BC’s

- Cast features

- Component and full system level FE/CFD models

- Parametric FE/CFD

- design features

- styling lines

- Sections

- Proportions

Parametric feature:

- Holes

- Ribs

- Bulkheads

- Crush-initiators

We provide exceptional CAE Services and our commitment to provide industry leading Morphing Parametrization to the global clientele has continued to strengthen our reputation making us the chosen partner for engineering service in the market. We promise you the advantage of: