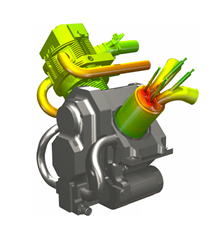

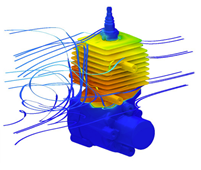

Thermal analysis aids in examining the effects of heating and cooling methods, as well as the development of more efficient and environmentally friendly products. The key to designing effective coolers, heaters, or heat exchangers is to efficiently combine heat transfer in fluids and solids. Conjugate heat transfer (CHT) methodologies are used to study the effects of temperature fluctuations on a design and validate product decisions early in the development process .While analytical solutions exist for some simple problems, the majority of industry relevant applications require the use of computational methods. With DEP’s expert support and advanced technologies, we will be able to provide custom-tailored quality solutions for precise heat transfer rate calculations and implement cooling capacity projects.

Domain Expertise

CHT Services:

DEP has decades of engineering expertise in providing detailed thermal analysis to investigate and solve problems caused by conjugate heat transfer. Our more intuitive simulation techniques link a thermal analysis with a structural and fluid sections to simulate multiple physics components at the same time.

Our experience in thermal analysis covers:

- Heat transfer analysis of devices and systems with liquids, solids and gases

- Industrial machines and electronic devices performance prediction and optimisation

- Optimization of thermal response and heat transfer efficiency

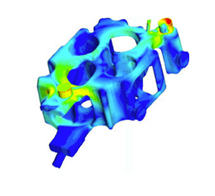

- Analysis of failures caused by thermal effects

- Analysis and optimization of heating/cooling devices

- Engineered material design for insulation and high thermal conductivity

- Evaluation of heat transfer capabilities of the product

- Measurement of surface temperatures and hot spot regions

- Design optimization for improvement in heat transfer rate and cooling capacity

Industry specific analysis includes:

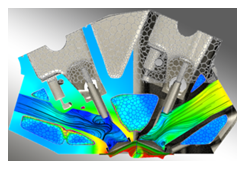

For Coolant study in Turbines: CHT can be performed to improve cooling performance of the water jacket and increase engine life. Advancements in cooling for applications such as gas turbines components require improved understanding of the complex heat transfer mechanisms and the interactions between those mechanisms, which our engineers can perform without hassle. Critical cooling applications often rely on multiple thermal protection techniques, including internal cooling, external film cooling, etc. which are efficiently used by our analysis to cool components and limit the use of coolant.

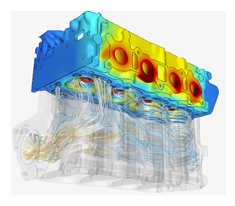

Engine Temperature Study for various industries: We do extensive support for Motor and Battery CHT Analysis to get optimized design for High voltage systems. Conjugate Heat Transfer analysis provides the temperature distribution in solid and coolant of the engine and clear insight on velocity distribution and mechanism of heat transfer of coolant. Results of CHT analysis become input to structural simulations as thermal loads. We have a wide experience in Engine CHT Analysis for various type of engines like

- Bikes

- Passenger Cars

- Racing cars

- Commercial Vehicles

- Marine

- Agricultural equipment

- Earth-moving equipment

We provide exceptional CAE Services and our commitment to provide industry leading CHT Analysis to the global clientele has continued to strengthen our reputation making us the chosen partner for engineering service in the market. We promise you the advantage of: