Remeshing and re-assembly

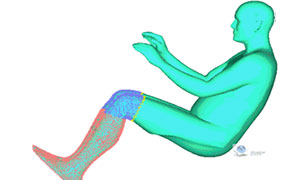

Remeshing and re-assembly is a powerful meshing technique, which can make changes in the meshes and also helps in repairing the already designed meshes according to the need. Remeshing technique is highly useful technique preferred by DEP (Detroit Engineered Products) to make the necessary changes in the meshes which are already designed by re-calculating the values.

Thermal and combustion Remeshing and re-assembly technique is one of the useful procedure offered by mainly preferred in the mechanical engineering industry. It is mainly used for developing post-process polygon meshes, which are designed using digitized sessions. The available remeshing tools reassemble the meshes under various techniques such as digital operations and interactive mouse-click sessions. The remeshing mechanism is very powerful and it has become part of business environment of India and USA. The Remeshing and re-assembly can be dealt at different levels such as the lower level deals with edge-flip and vertex and the higher-level use simplification and subdivision.

The spontaneous selection method makes remeshing highly significant and it offers complete support the users. The various tools and technologies have become part of software system which can easily overcome the unwanted and unimportant flaws from the model s and reassemble it s structure making it more flexible to use. Remeshing and re-assembly processing is a part of Thermal and combustion. Remeshing and re-assembly procedure can automatically redesign the structure using 3D digitization session which can degenerate triangles and topological artefacts. Also it can control the isolatd vertices and the noise completely.

The advanced methods of remeshing and re-assembly work automatically and offer complete control to the users to handle the complete editing process. Thermal and combustion advancement has become part of the remeshing procedure and it id followed across India and USA using 3D digitization and 3D geometry as part of the cutting edge technologies.

Remeshing and re-assembly are the most useful techniques used in the industry today. Remeshing saves time, energy and the resources while making the necessary changes. DEP (Detroit Engineered Products) supports remeshing which is a powerful and essential technology. It is effective in managing the industrial requirements under the constraints time, money and the trained manpower.