DEP’s MeshWorks software offers a Modeling module that includes a range of interactive and automated functions for creating complex system-level models of vehicles, engines, aircraft, ships, and more. The primary goal is to reduce the time required for model assembly when compared to traditional meshing applications. With MeshWorks, DEP’s engineers have created a tool that can assemble models of even the most intricate components in a condensed timeframe.

MeshWorks boasts an extensive variety of model assembly functions, including seam welds, spot welds, adhesives, bolt connections, and contacts, among others. Each connection category offers significant depth, such as solid bolt, 1D bolt, and rigid bolt connections. All connection creation functions are either fully or highly automated. MeshWorks assembly functions comprehensively address sheet metal assemblies, cast/machined component connections, and plastic assembly connections, among others.

Modelling module functions:

Spot Welding:

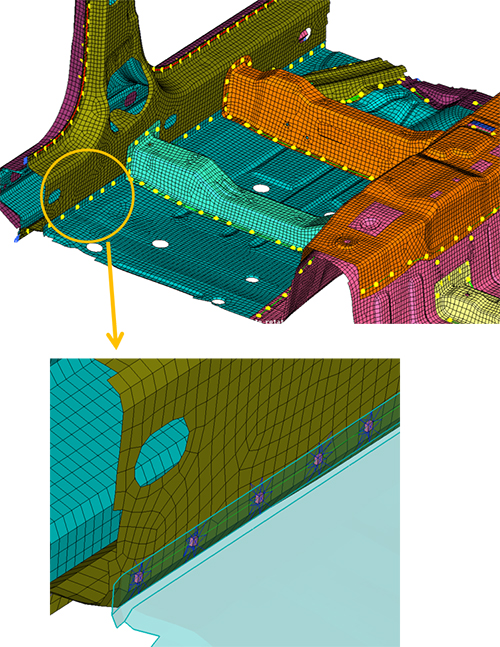

MeshWorks enables the creation of spot welds by choosing nodes from the flange area and selecting the appropriate connecting parts while specifying the desired weld type. When dealing with spot-welded structures, such as automotive bodies, various types of attributes like crash, NVH, and durability can be automatically generated for the weld elements. Additionally, specialized features like weld force failure and heat affected zone modeling can provide more detailed modeling of the welds. In the early stages of product development, spot weld lines and points can be generated automatically using the part meshes.

SEAM WELDING:

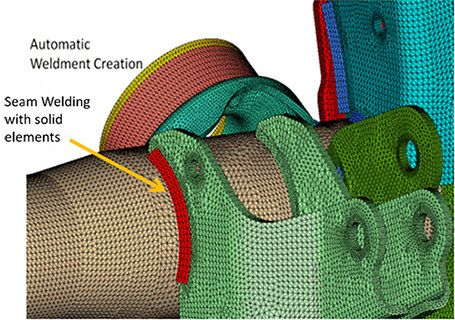

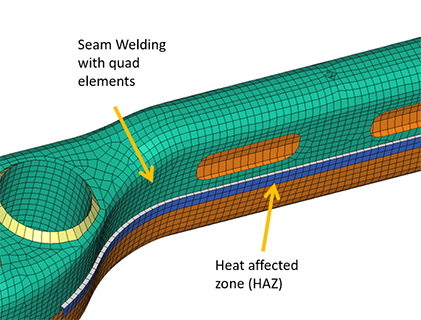

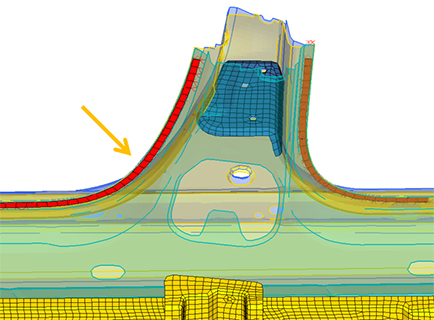

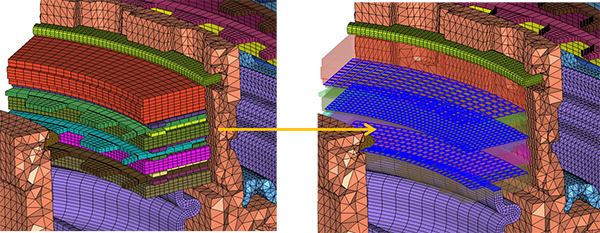

To create a seam weld, we can select nodes from the flange area and master and slave elements, while specifying the required weld and align type. Weld elements for fabricated structures that involve seam welds can be generated using various configurations, including quad, beam, solid, and rigid elements. For detailed weld modeling, solid elements can be used, and there are options to automatically create weldments with node-to-node matching connections to the surrounding parts.

ADHESIVE BONDING:

To create an adhesive bond, we can select nodes from the flange area and connecting parts, while specifying the required adhesive type. Solid bond elements will be automatically generated in areas where adhesive bonding is necessary and will be connected to the surrounding part meshes through connection equations and contacts.

BOLTED CONNECTIONS:

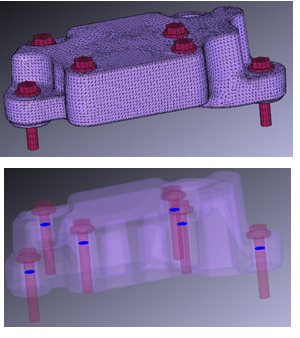

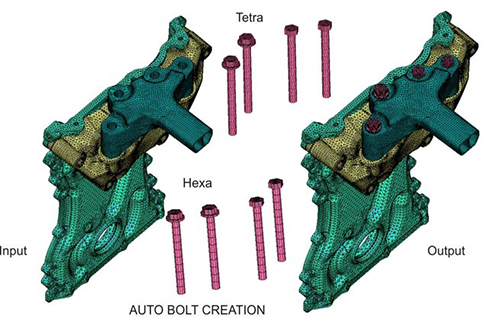

A wide variety of bolted assembly connection elements can be created automatically. Through bolts, screws, detailed metric bolt modeling, bolt connections with beams/rigids, and so on are used. By selecting the bolt center node and defining the bolt dimensions in MeshWorks, this feature is commonly used to produce solid bolts.

The steps are as follows:

Multiple bolts with Pre-tension sections and values can be created in a single click by selecting multiple center nodes and bolt specifications.

While creating a bolt, we can define bolt geometry such as size, type of bolt, washer layers, and so on, as well as property definitions.

There are other options for automatically creating Bolt connections by detecting the hole.

CONTACTS CREATION:

Automatic contact surface development between all components of an assembly allows for extensive contact modeling. Contact pairs can also be formed between contact surfaces with suitable interface conditions such as friction, thermal properties, and so on. The Auto Contact Creation tool enables the user to quickly and conveniently create contact surfaces and contact pairs. Auto Contact Creation includes an automatic contact pair, contact control, contact interface, and pre-tension surface.

Key Modeling Features:

Loads and Boundary Conditions:

MeshWorks is a powerful tool that allows engineers and designers to quickly and efficiently apply a wide range of loads and boundary conditions to solve different types of problems.

MeshWorks provides an include file management system for large-scale system models. This allows users to easily organize sub-assembly data into include files and perform data manipulation operations across different files.

During the early stages of design and development, connector data may not be available. However, MeshWorks offers the ability to automatically generate connectors by detecting gaps between mating parts and creating various types of connectors, such as weldlines (Seam & Spot), bolt connections, and more. MeshWorks can even auto-generate bolt mesh, even if no bolt geometry is available.

Furthermore, MeshWorks enables the parametrization of connectors, such as Weld Length, Spot Weld Pitch, Length of Seam Weld Lines, and Skip Welds. This allows for subsequent optimization for manufacturing cost reduction. Parametrization can be done as an assembly across different connector types and associated parts, such as moving bolts and bosses together as a parameter.

MeshWorks also offers contacts management, allowing for the auto creation of contacts such as Shell to Solid, Solid to Solid, and Shell to Shell connections. It can detect auto closure, shell gap, over closure, and other issues for contacts. MeshWorks can even create connections at different depths, such as modeling HAZ (Heat Affected Zone) for sheet metal and solid structures.

When converting a model to different disciplines, MeshWorks automatically converts connectors to appropriate representations. It also provides the ability to morph connectors as a geometric feature, allowing for even greater flexibility and control over the design process.

Benefits:

When compared to traditional methods, the process of making spot welds with MeshWorks is substantially faster, requiring only 1 minute because to the number of possibilities offered in the weld function. This is especially advantageous when dealing with larger components,

Creating complex adhesive bonds using conventional methods is time-consuming, but with MeshWorks, the same task can be completed in just 2 minutes using various options available. MeshWorks is particularly beneficial for larger component models as it significantly reduces the time required compared to conventional processes.

In the conventional process, creating 20 bolts with pretension sections would take around 3.5 hours. However, with MeshWorks, the same task can be completed in under 30 minutes.

In MeshWorks, the user has the ability to unselect undesired areas and choose additional ones for the contact pair surfaces. Furthermore, an automatic creation of card images for all the surfaces is possible in MeshWorks.

- MeshWorks offers the ability to co-create, which means that when creating a bolt assembly, not only are the 3D bolts created, but the contacts and pre-tension are also simultaneously generated. This makes the process of connecting the dots much more efficient.

- MeshWorks also allows for the optimization of welding, including the reduction of the number of seam welds and spot welds, as well as the reduction of weld length and adhesive length. This can lead to manufacturing cost reduction through the parametrization of connectors.

- In addition to its time-saving capabilities, MeshWorks also provides high-fidelity modeling, including HAZ modeling, which can result in higher and better accuracy in analysis results.

- With MeshWorks, up to 60% of the time required for modeling can be reduced. This is due to the user-friendly nature of the tool, which requires minimal inputs to perform functions and therefore only requires minimal training.

How does it compare to other similar software?

| Features | Meshworks – Modeling | Other Softwares Flow |

| Automation in assembly connection functions | Unique and unparalleled | Does not provide a distinctive and unparalleled |

| Co-creating connectors while auto-generating parts and assemblies | Exclusive feature | Standard features |

| In-depth modeling of connectors, including HAZ modeling in solids | Clear differentiator | Clear differentiator |

| Advanced assembly connection functions and modeling capabilities | Top choice for those seeking | Not a preferred option |

| Comparison to other software | The level of automation and efficiency is at its maximum. | No other software offers similar level of automation and efficiency |