Latest News

Industries

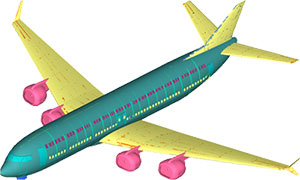

AEROSPACE & DEFENSE

DEP offers services in the following areas in Fixed and Rotary Wing aircrafts.

- Detailed Design

- Structural Analysis

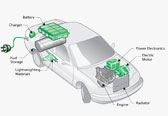

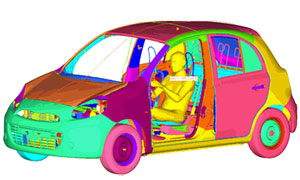

AUTOMOTIVE

DEP provides effective solutions to automakers and suppliers by leveraging CAE driven design at a very competitive cost.

Learn More

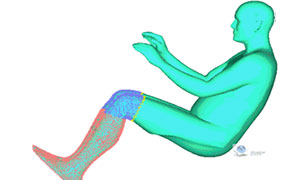

HEALTHCARE

Virtual simulation and validation for implants have ability to reduce the necessity to produce expensive prototypes.

Learn More

MARINE

DEP engineering team have executed projects & programmes for the Marine Industry. The capabilities include both structural as well as

Learn More

HEAVY ENGINEERING

DEPs heavy engineering offerings cater across agricultural equipment, construction and mining equipment. Our mesh modeling tools,

Learn More

OIL & GAS

DEP has a very strong engineering team to address & service complex engineering projects of the most dynamic industry in the world

Learn More

POWER & UTILITY

DEP’s innovative technology support for Power & Utility sector can mitigate the potential risks that are associated with cost effective and reliable power generation

Learn More